dhs Dietermann & Heuser Solution GmbH | Zeiss AxioImager M2m with dhs-Cleanalyzer professional for Residual Dirt Analysis

dhs Dietermann & Heuser Solution GmbH

Herborner Str. 50

35753 Greifenstein-Beilstein

GERMANY

Phone: +49 2779 91200

Mail: vertrieb@dhssolution.com

WEB: https://www.dhssolution.com/en/

Details

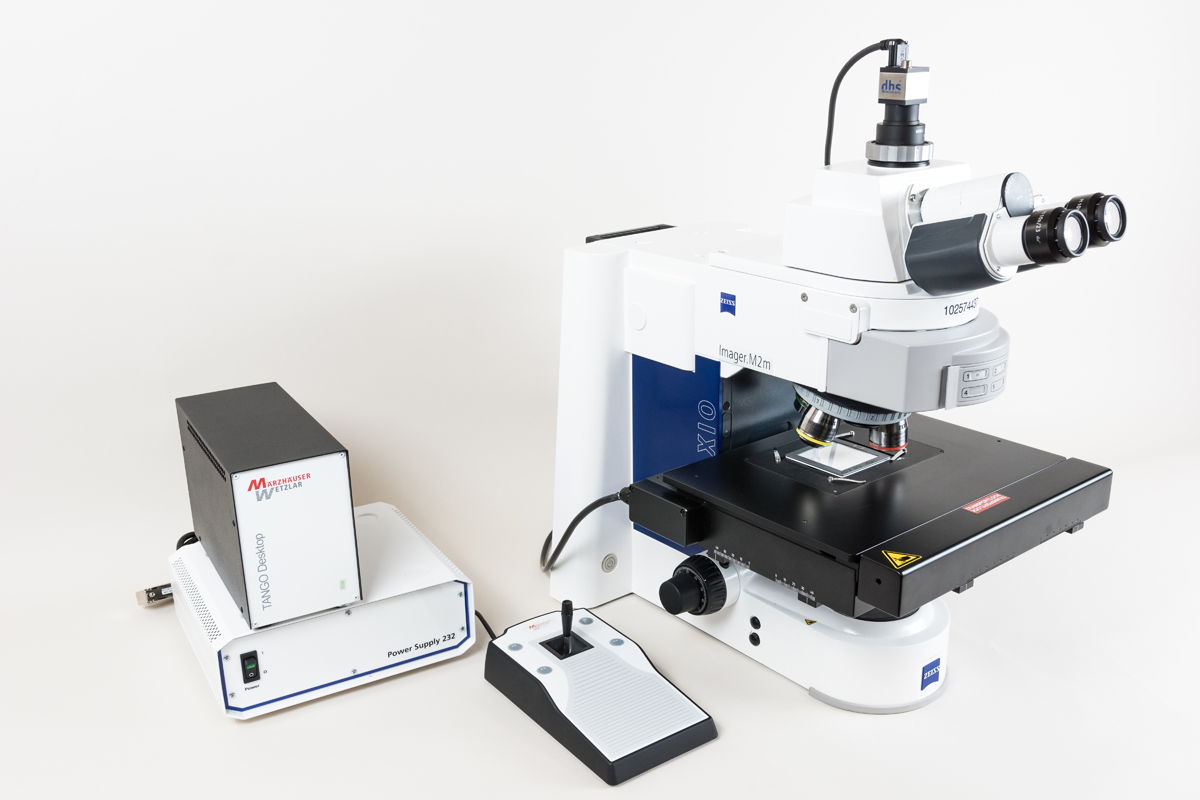

dhs Dietermann & Heuser Solution GmbH | Zeiss AxioImager M2m with dhs-Cleanalyzer professional for cleanliness analysis

Microscope: Open microscope system for automated material research. Simplify your workflow for light microscopic investigations in advanced material research and benefit from precise and reproducible results with ZEISS Axio Imager 2. This system is designed with material research applications in mind, allowing you to expand your system with dedicated solutions such as particle analysis, confocal microscopy, or correlative microscopy.

dhs-Cleanalyzer® – “Professional”

Freely configurable cleanliness systems – with already available microscopes. Fully automatic example system consisting of:

ZEISS microscope AxioImager, cross table with motorized x-/y-axis, tango-steering, adjustable LED lighting, and dhs-MicroCam® 2213.

- Standard-compliant analyses for particle sizes from 5µm

- High-quality microscope suitable for varied analytical settings of tasks

- Upgradeable with all dhs software modules, according to the application

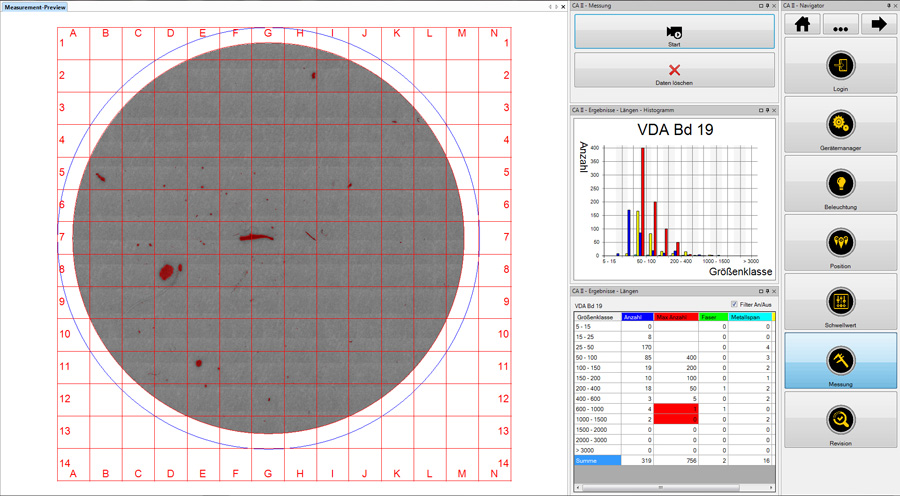

Software analysis with dhs-Cleanalyzer

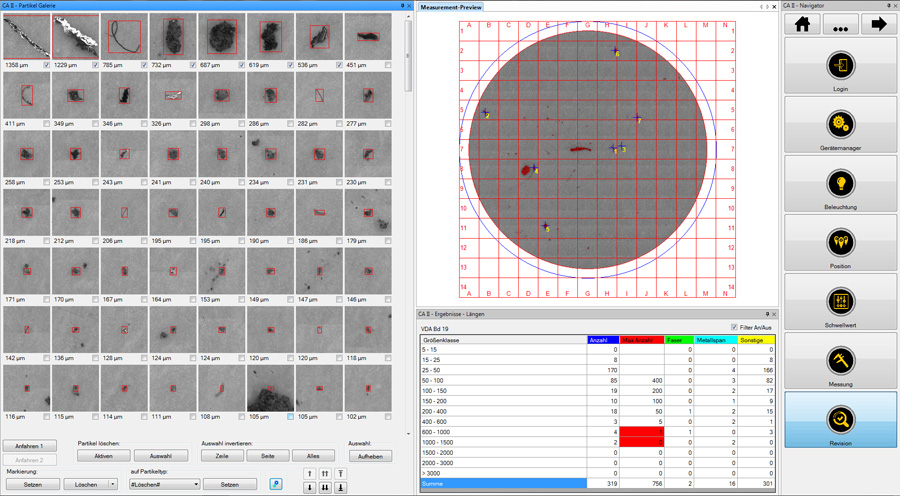

- Standards-compliant analysis as per VDA Vol. 19/V2, ISO 16232, ISO 4406, SAE AS 4059, etc.

- Detailed presentation of measured values

- Adjustable pre-classifiers (e.g., fiber criteria, coverage density as a percentage)

- Immediate result checks (“live” evaluation tracking)

- Short throughput times

- Classification of all particles

- Z measurement

- Trend analysis option – long-term evaluations

Visualization of all particles by means of a gallery view for:

- A good overview

- Faster working

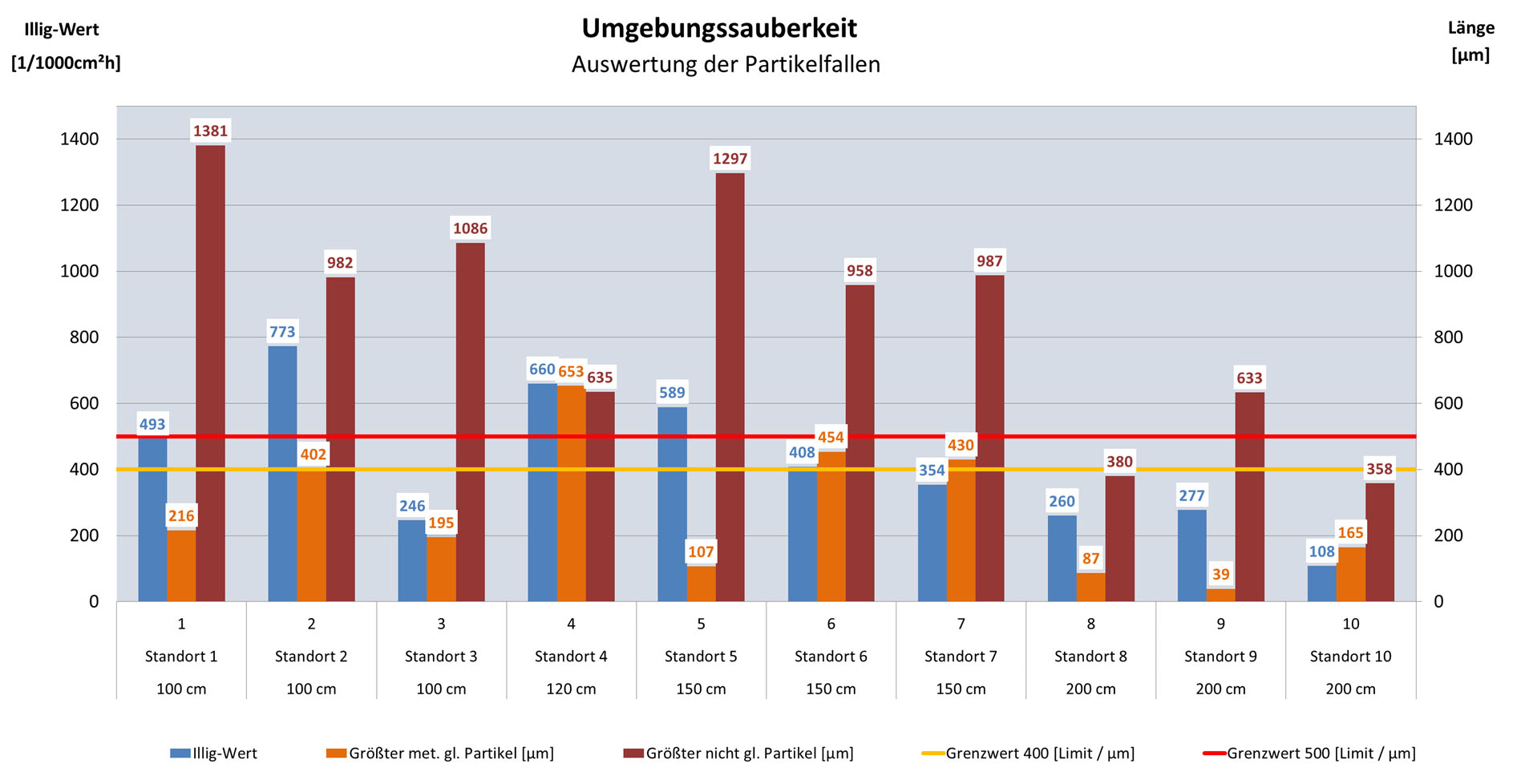

Particle and hall monitoring

With the help of particle traps set up in the production hall, particle precipitation can be detected at an early stage. Disruptive influences affecting cleanliness in the assembly environment can be investigated and assessed.

The dhs-Cleanalyzer® Scan evaluates the contaminated particle traps using VDA 19.2 (Illig value): sedimented particle precipitation from a variety of locations and collection times is calculated and compared using a formula and summarized to give a measured value.

Technical Data:

| Category | Description |

|---|---|

| Microscope | ZEISS AxioImager M2m |

| Cross Table | Motorized x-/y-axis |

| Control | Tango steering |

| Lighting | Adjustable LED lighting |

| Camera | dhs-MicroCam® 2213 |

| Particle Size Analysis | Standard-compliant from 5 µm |

| Software Compatibility | Upgradeable with all dhs software modules |