dhs - Software Modul Weld Seam Measurement

dhs Dietermann & Heuser Solution GmbH

Herborner Str. 50

35753 Greifenstein-Beilstein

Germany

Phone: +49 2779 91200

Fax: +49 2779 912099

Mail: vertrieb@dhssolution.com

Website: www.dhssolution.com

Managing Director: Christian Dietermann & Julian Schäfer

Details

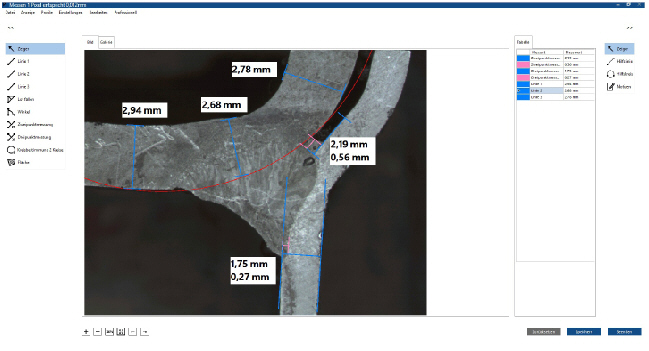

The dhs software module "Weld Seam Measurement" has been specifically developed for the evaluation of fusion joints.

Especially in automotive construction, steel construction, and pressure vessel manufacturing, there are components that consist of numerous welding connections. With the dhs module, all necessary inspection processes are consolidated into measurement profiles, allowing the inspection process to be conducted efficiently and in parallel with production. Additionally, statistical evaluations of individual components and measurement processes can be generated to assess the entire production process in the long term.

Measurement functions:

- Pore measurement

- Soldering measurement

- Workpiece thickness

- Seam measurement

- Penetration

- Gap, a-measure

- Groove angle

- And much more

Auxiliary functions:

- Rotatable measurement

- Hideable measurement values

- Digital magnifier (configurable for precise placement of measurement points)

- Editable measurement lines (end marks, line thickness, color)

- Continuous display of measurement values during the measurement process

- Setting warning limits for measurement values

Storage options:

- All image and measurement data are stored in the dhs image database®. Special database fields (e.g., measurement values, measurement specifications, measurement results) are created in the database, enabling precise assignment.

Statistical evaluations:

- Through the integrated export interface in the basic module of the dhs image database®, statistical evaluations of individual components and specific measurement results are generated in various formats (e.g., qs-STAT or SAP).

Norm-compliant testing:

- Testing according to DIN ISO 5817 and other customer-specific requirements and standards

- Clear display of measurement values in tabular form

- Summarizing measurement functions into test profiles for reproducible measurement processes

- Display of tolerance deviation from the selected component specification

Pore measurement:

- An extension of the "Schweißnaht" module also includes the norm-compliant measurement of pores. Individual pores are evaluated for size and area. The results are stored together with the measurements of the welding seam in corresponding data fields.

Report generation:

- With the additional module "Bericht," we offer the ideal tool for professional documentation of your work. All previously determined images, texts, and measurement results from the database can be compiled and output as an inspection report.

Suitable hardware:

- For rapid inspection of welding seams in the low-magnification range, the dhs-EasyController 4K is a suitable option (in addition to stereomicroscopes and macroscope). It is a compact, inverse optical system with an integrated digital camera and LED ring light. When combined with our software modules "dhs Schweißnahtvermessung" and "Berichtserstellung," it becomes an ideal system for efficient evaluation of samples and workpieces directly in production.

Configurations

Reviews

Select your country to view all the provider contacts: